A digital twin is a virtual representation of a real product that reflects its current state. It enables testing, simulation and analysis of a product before, during and after it is in use. More details on this have already been explained in our previous articles The phenomenon of the ‘digital twin’ and Digital twins: data streams as the key to the life cycle.

The digital thread maps the complete data and information chain of a product.

From the initial concept through development and production to service, it documents all relevant information and decisions in a consistent and interconnected manner. It ensures that data is traceable, consistent and usable across departments.

The digital thread thus forms the basis for a digital twin to function in an up-to-date and reliable manner.

Why are digital twins and digital threads compared in the product lifecycle?

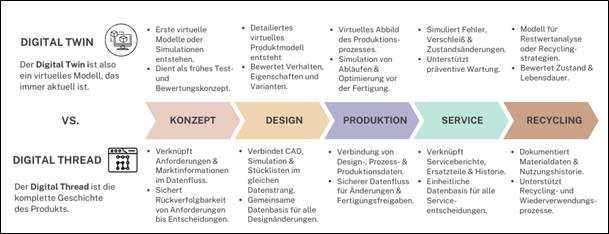

The terms digital twin and digital thread are appearing more and more frequently in the product lifecycle. Both are crucial for modern PLM strategies, but they fulfil completely different tasks. The graphic below clearly shows how the two concepts differ along the phases of concept, design, production, service and recycling.

The infographic clearly illustrates these relationships using the five typical PLM phases: concept, design, production, service and recycling. For each phase, the respective roles of the digital twin and digital thread are concisely presented, from initial simulations and data flow to recycling. This makes it clear that the digital thread is the data thread that connects everything, and the digital twin is the virtual image that makes everything visible.

Why both concepts belong together?

Only the combination of Twin and Thread creates a holistic, digital understanding of the product:

- Digital Twin shows what the product looks like, how it works and how it behaves.

- Digital Thread connects where the data comes from and how it changes over its lifecycle.

This creates a genuine end-to-end digital basis for development, manufacturing and service. A core principle of modern PLM strategies.

Conclusion

Digital twin and digital thread are much more than just buzzwords in Industry 4.0. They form the basis of modern, data-driven product development. Companies that integrate both concepts benefit from more efficient processes, better decisions and higher product quality, including a continuous data flow.

Deutsch

Deutsch